Linear module is the most commonly used standardized module in automation equipment, because of the wide variety of module sliding table, in the selection process, if the selection is wrong, it will bring various problems to the performance of the equipment and the promotion of the project, so the selection of linear module is very critical.

one. The selection of module slide table can refer to the following steps:

1. Use environment: according to the use of the environment to determine the general environment, clean environment, harsh environment.

2. Installation method: Determine whether the module sliding table is installed horizontally, on the wall or vertically.

3. Load: Determine the load to be carried by the module slide.

4. Effective stroke: the direct effective stroke of module operation.

5. Speed: calculate the speed and acceleration of the module slide.

6. Allowable torque: Calculate the axial torque value at static constant speed and acceleration and deceleration state: Ma, Mb, Mc.

7. Accuracy: Specify the required repeated positioning accuracy, walking parallelism and other parameters.

8. Motor installation: The commonly used module slide installation mode has direct connection type, motor left side installation, motor right side installation, motor bottom side installation, etc.

9. Limit switch: module slide limit switch mode.

10. Motor: Determine the motor specifications and power of the module slide table.

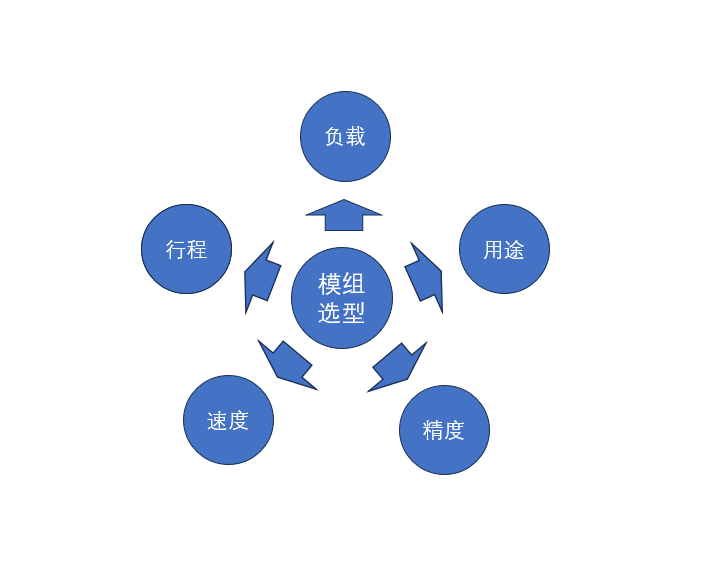

two. Schematic diagram of key elements of module selection

Three. Module selection also needs to pay attention to the following matters

1. If the load exceeds 30kg, it is necessary to confirm the overall size of the loaded carrier and the installation position on the module.

2. When the stroke exceeds 700 mm, the lead screw module needs to consider the lead screw slender ratio.

3. When the stroke exceeds 1000 mm, the rigidity of the top cover should be considered to prevent abnormal noise during operation.

4. When the line speed is greater than 2m/s, the guide life is mainly considered; when the acceleration is greater than 1G, the overall rigidity should be considered.

5. The portable weight of the linear module is closely related to the speed, acceleration and torque value, so the load can not be simplified, and the load weight and load torque value need to be checked at the same time.

6. When the center of gravity of load deviates from the center of the slide seat, the generated torque will act on the guide rail of the electric slide table. Please be sure to check whether the torque value is within the allowable range.

The above is the knowledge about linear module selection shared by Suzhou Hopu Technology. I hope it will be helpful to you! If there is a demand for the linear module, or you have any problems in actual use, you can call our company at any time to contact! Thank you!

Hopu (Suzhou) Automation Technology Co., LTD., founded in 2010, has been focusing on the development and application of industrial control transmission products for more than 10 years, and is committed to providing customers with reliable transmission products and professional solutions, including high-precision electric slide, electric cylinder, hollow rotating platform, planetary reducer and so on. We always adhere to the original intention of "ingenuity casts quality, sincerity wins trust", and look forward to working with you to create a better future!

CopyRight © 2013 All Rights Reserved.

HOPE (Suzhou) Automation Technology Co,, Ltd. CopyRight 备案号:苏ICP备2024081346号